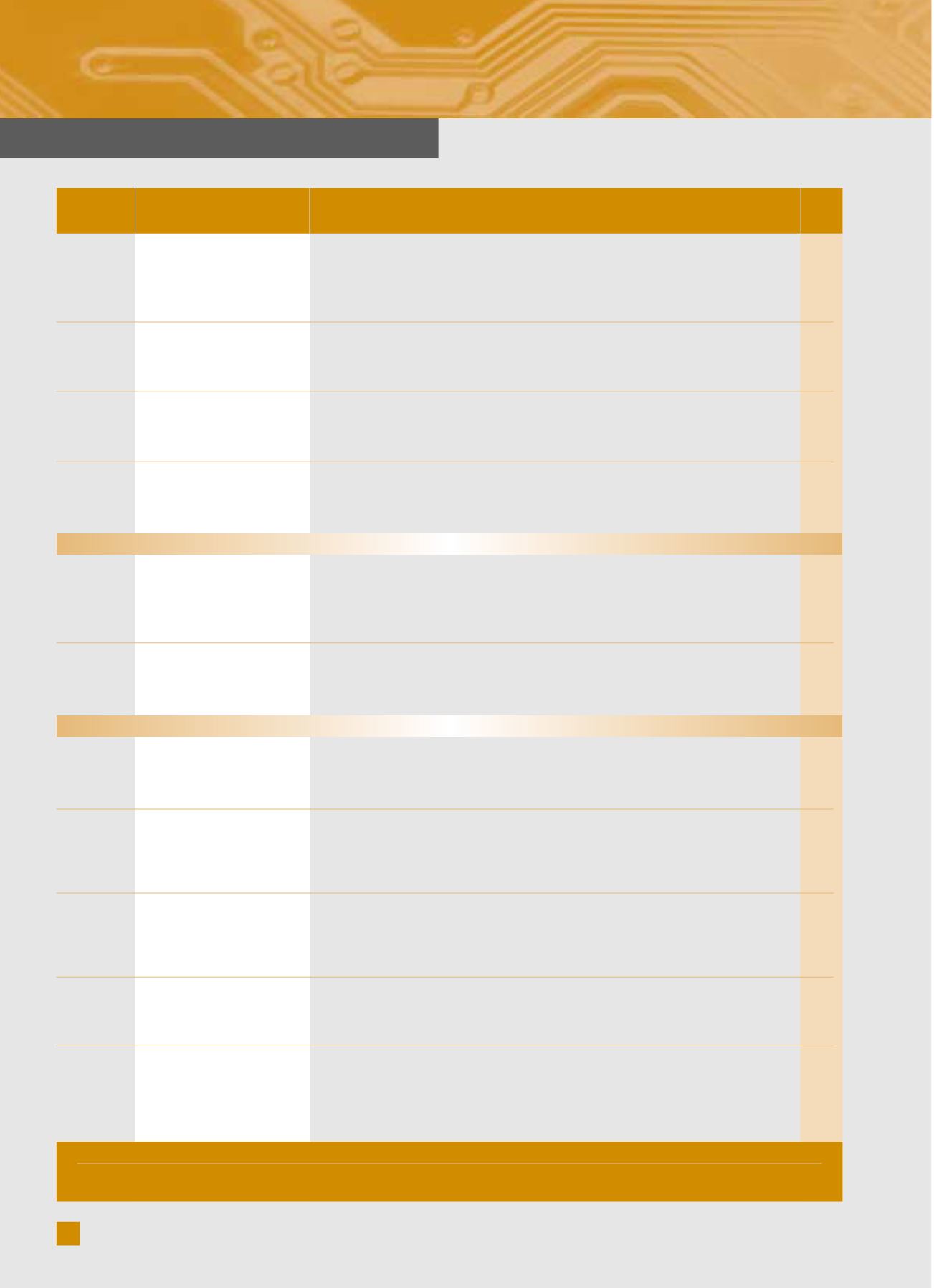

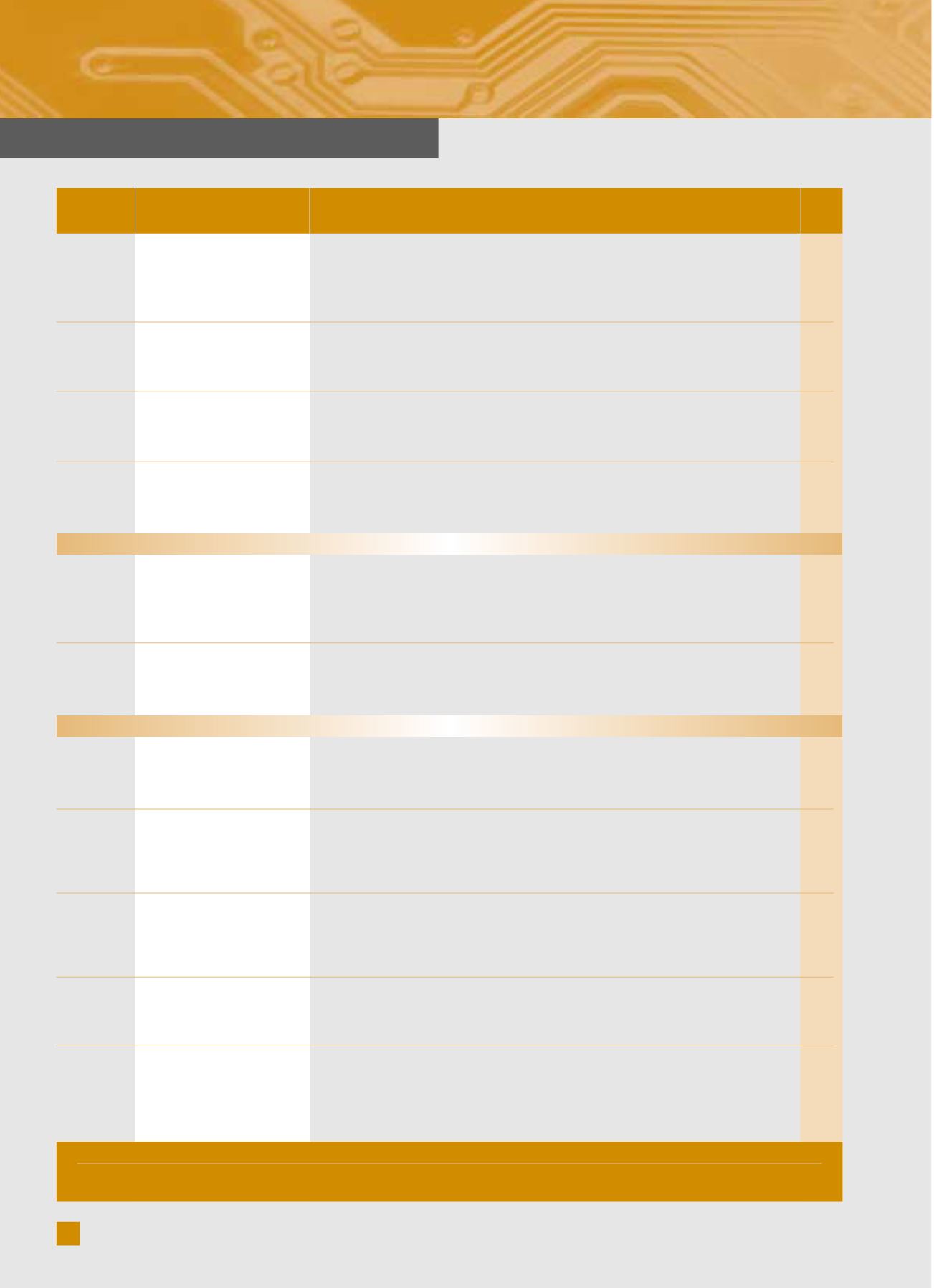

28

K · È Ó Ô Ù Ô Ì › · , Œ Ú Â ˘ Ó · Î · È ∆  ¯ Ó Ô Ï Ô Á › ·

Û˘ÓÂÚÁ·Û›Â˜

ÚÔÛÊÔÚ¿ Ù¯ÓÔÏÔÁÈÒÓ

DE

DE

DE

DE

UK

FR

ES

PL

UK

DE

FR

Zircon-dioxide lambda sensors for the

glass industry

High-performance Cements by

Refinement of Ordinary Portland Cement

High Kinetic Processing of Enamel

NOx burners (oil and gas) for glass

furnaces

High Speed valve for fluid control

applications in the life sciences/medical

sector

New line of goods able to combine

various adhesives and matters on the

same label

System for the purification of sea water

powered by air energy

System for storm water cleaning from

heavy metals, hydrocarbons and other

contaminations

Marker substance for pollution

monitoring

Machine System for defibration, mixing

and compacting (MSZK)

Final Waste Stabilization

A German SME specialised in energy saving and environment protection technologies for the glass industry offers a

lambda sensor for oxygen measurement in glass furnaces with significantly increased lifetime. The sensor is suitable for

process control, even for near or below stoichiometric conditions (NOx emission!). The sensors are available as complete

oxygen measurement system. Commercial agreements with technical assistance with engineering companies related to the

glass industry are aspired.

A German company is developing a high energy milling (HEM) process for operating of Ordinary Portland Cement (OPC).

The HEM offers a fast process route for particle size reduction of OPC. In this process OPC has been mechanically refined

to 2 and 9 mm (50 and 90% PSD, respectively) and mechanically activated through HEM. The observed setting time is 2

to 3 min only. Partners are sought for technical and manufacturing co-operation.

A German company developed a high energy milling (HEM) process for operating of enamels. The HEM offers a dry

process route for particle size reduction of glaze frits, by which the frits with up to 10 mm diameter can be reduced down

to a d50-value of about 6 Ìm. In comparison with the conventional route it is 600 times faster in process duration and

powder particle size is 3 times finer. Partners are sought for technical cooperation and manufacturing agreements.

A German SME specialised in energy saving and environment protection technologies for the glass industry offers NOx-

burners for the glass industry. The burners, available for heavy oil and natural gas, are superior in energy consumption,

DeNOx-emissions and maintenance expenditures. The company is looking for engineering companies working for the glass

industry (process control) and aspires commercial agreements with technical assistance.

A UK company has developed a high speed, bi-stable pinch valve for fluid control applications in the life sciences/medical

sector. The core technology combines a high-power permanent magnet with short pulses of electric power to catapult a

spring-loaded armature between two stable positions. Advantages include portability, high power efficiency, precise

delivery, scalability and digital control. The company is seeking industrial partners interested in a

manufacturing/licensing agreement.

A French company, specialized in developing industrial labelling equipments, has developed and patented a new process

able to combine various adhesives and matters on the same label. So, this new process allows the production of labels

having for example tearable and non-tearable parts, permanent, repositionable and neutral adhesive parts, opaque and

transparent parts, etc. The SME is looking for partners (label manufacturers) to conclude license agreements.

A Spanish researcher has developed a system for the purification of sea water powered by air energy. The main advantage

is that the use of the spiral conveyor for pulling and introducing the steam in the heat exchanger produces an important

saving of power. This researcher is looking for partners interested in investing, producing, and marketing/using this

system.

A Polish SME specialises in consulting and services in the field of environmental engineering and technologies

(neutralisation of industrial wastewater, neutralisation of used reagents and chemical wastes, liquidation and

demolishing of closed, non-operated industrial plants and structures). The company has developed a system for storm

water cleaning from heavy metals, hydrocarbons and other contaminations. The company seeks partners interested in

implementation of this technology.

A leading UK research organisation has developed a method of releasing a marker substance into a fluid over a period of

time without need for repeated manual doses, and without the need to provide ongoing power. Liquids may be dosed

manually for single events or by a pumping system where an ongoing trace is required. The organization is looking for

partners active in the areas of water quality management and pollution monitoring for further development and

licensing.

A German SME has developed the heart of a processing plant for thermo-mechanical treatment of processing materials in

closed substance circuits. Range of activity is defibration of raw materials growing again. Applying this procedure opens a

multitude of novel recycling possibilities for non-depleting resources, organic residues and different kinds of waste. The

company is looking for industry partners for commercial agreement with technical assistance.

A French research laboratory has developed a new matrix for final waste encapsulation. First developed in order to solve

the problem of stabilization of high-level radioactive waste, it can be used for other types of final waste, in particular

those containing mineral elements. Results obtained with this new, patented matrix are very superior to those obtained

with other confinement matrices. The laboratory is looking for co-development or a license agreement with an industrial

partner.

O T H E R I N D U S T R I A L T E C H N O L O G I E S

P R O T E C T I N G M A N A N D E N V I R O N M E N T

∫ø¢π∫√™

ƹƤê

¶ ∂ ƒ π § ∏ æ ∏

̿İ

TO 0405

STG1

04 DE XE

0AER

04 DE XE

0AES

TO 0405

STG2

TO UK IRC

EAST 04 026

PDL040600

1-O

SYST/MAY 04

OPI-TO530

TO UKIRC

SWRD 04 011

TAC

19/05/2004

04 FR AA

0AF7

K¿ÓÂÙ ÙȘ ‰ÈΤ˜ Û·˜ ·Ó·˙ËÙ‹ÛÂȘ ÛÙȘ ‚¿ÛÂȘ ‰Â‰ÔÌ¤ÓˆÓ ÁÈ· ÚÔÛÊÔÚ¿ / ˙‹ÙËÛË Ù¯ÓÔÏÔÁÈÒÓ ÛÙË ‰È‡ı˘ÓÛË:

¶ÏËÚÔÊÔڛ˜: EKT, EÏÏËÓÈÎfi K¤ÓÙÚÔ AÓ·‰È·ÓÔÌ‹˜ K·ÈÓÔÙÔÌ›·˜, η K. M·ÏÈ·ÎÚ›‰·,

TËÏ.: 210 72 73 903, Fax: 210 72 46 824, e-mail: